Where the Nusselt, Reynolds, Prandtl and Knudsen Numbers are all non-dimensional quantities. The physics of fluid flow and convective heat transfer are inextricably linked by relationships of the general form

Typical hot wire sensor Calibration of Cylindrical Sensors The wire is supported on prongs that are embedded in non-conducting (often ceramic) material. For work in gases, platinum-coated tungsten of 5 mm diameter is most commonly used (see below) as the sensing element although other sizes and materials are sometimes used.

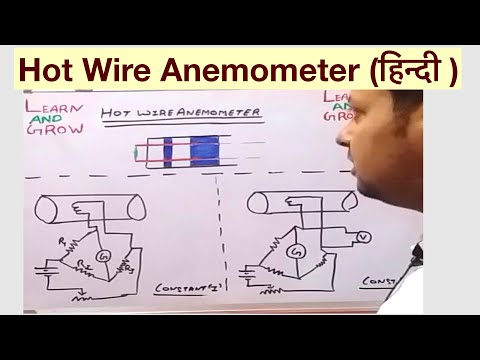

To optimise the frequency response of an anemometer, the probe should have as small a thermal inertia as possible and this is consistent with the requirement of a small size. Of these, most are simple hot-wires since these offer the greatest flexibility of use in restricted, often highly unsteady turbomachine environments. Sensors used for the measurement of velocity in turbomachinery investigations are invariably of the cylindrical type. Until the advent of laser anemometry or rotating frame instrumentation, this was the only available technique for the acquisition of rotating frame data. By a transformation of co-ordinates, the time-history of the flow behind a rotor can be converted into a pitch-wise variation in the relative frame so that it is possible to determine the structure of the rotor relative exit flow. Thermal anemometers are also ideally suited to the measurement of unsteady flows such as those that arise behind rotating blade rows when the flow is viewed in the stationary frame of reference. Hot-wire anemometers have been used for many years in the study of laminar, transitional and turbulent boundary layer flows and much of our current understanding of the physics of boundary layer transition has come solely from hot-wire measurements. Most sensors are operated in the constant temperature mode. The basic principles of the technique are relatively straightforward and the probes are difficult to damage if reasonable care is taken. Thermal anemometry enjoys its popularity because the technique involves the use of very small probes that offer very high spatial resolution and excellent frequency response characteristics. Hot-film sensors may also be cylindrical but may also take other forms, such as those that are flush-mounted. Hot-film sensors consist of a thin layer of conducting material that has been deposited on a non-conducting substrate.

Hot-wire sensors are, as the name implies, made from short lengths of resistance wire and are circular in section. Cylindrical sensors (hot wires and hot films) are most commonly used to measure the fluid velocity while flush sensors (hot films) are employed to measure the wall shear stress. Two fundamentally different sensor types will be discussed below. If only the fluid velocity varies, then the heat loss can be interpreted as a measure of that variable. The technique depends on the convective heat loss to the surrounding fluid from an electrically heated sensing element or probe. Thermal anemometry is the most common method used to measure instantaneous fluid velocity.

0 kommentar(er)

0 kommentar(er)